The Future of Manufacturing: How Large 3D Printers are Revolutionizing Production

How much do you understand about large 3d printer. In recent years, the advent of large 3D printers has significantly transformed the manufacturing landscape. These machines are not just larger versions of their smaller counterparts; they represent a paradigm shift in how products are designed, produced, and delivered. But what exactly makes these printers so revolutionary?

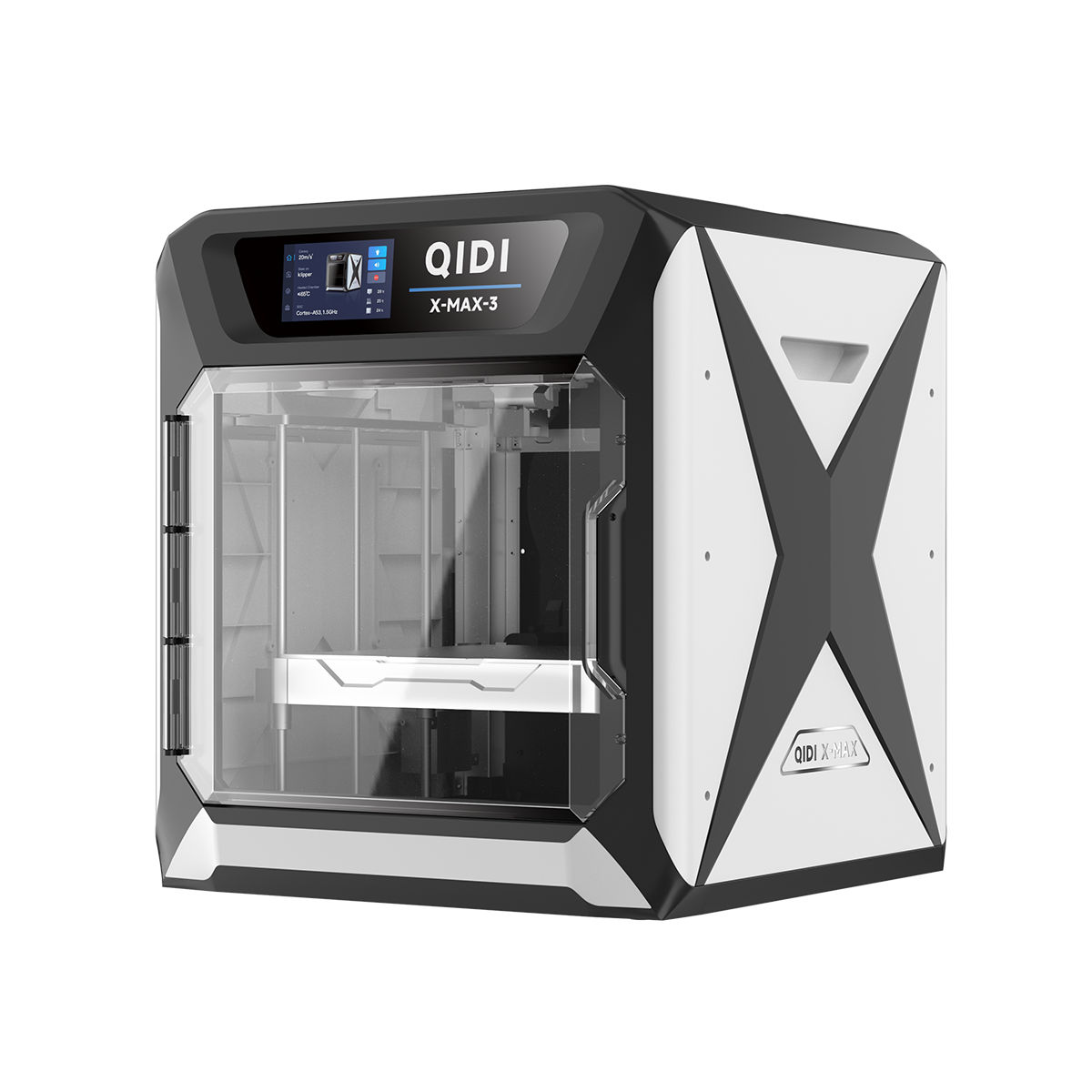

Understanding Large 3D Printers

Large 3D printers are capable of producing sizable components that traditional manufacturing methods struggle to create efficiently. They utilize advanced additive manufacturing techniques, which build objects layer by layer from digital models. This process not only reduces waste but also allows for complex geometries that were previously impossible to achieve.

"The ability to create intricate designs without the constraints of traditional manufacturing opens up a world of possibilities." - Industry Expert

Applications of Large 3D Printers

The applications of large 3D printers span various industries, including aerospace, automotive, and construction. For instance, companies like XYZ Corp have utilized large-scale 3D printing to produce lightweight components that enhance fuel efficiency in aircraft. Additionally, in the construction sector, large 3D printers are being used to create entire structures, reducing both time and labor costs.

- Aerospace: Lightweight parts for improved fuel efficiency.

- Automotive: Custom prototypes and production parts.

- Construction: Entire buildings printed on-site.

Benefits of Using Large 3D Printers

One of the most significant advantages of large 3D printers is their ability to reduce production time. Traditional manufacturing often involves multiple steps and processes, whereas 3D printing can streamline production into a single operation. Furthermore, these printers allow for rapid prototyping, enabling companies to test designs quickly and efficiently.

Moreover, the customization potential is immense. Businesses can create tailored products that meet specific customer needs without incurring the high costs typically associated with custom manufacturing.

Challenges and Considerations

Despite their numerous benefits, large 3D printers also face challenges. Material limitations can restrict the types of products that can be manufactured. Additionally, the initial investment for high-quality large 3D printers can be substantial. However, as technology advances and costs decrease, these barriers are likely to diminish.

In conclusion, the future of manufacturing is undoubtedly intertwined with the evolution of large 3D printers. As industries continue to explore the potential of these machines, we can expect to see innovative solutions that redefine production standards.

Explore More

For those interested in seeing large 3D printers in action, check out this informative video: Large 3D Printing in Action. References

|