Understanding FDM 3D Printing: Essential Components and How They Work

Fused Deposition Modeling (FDM) is a popular 3D printing technology that has made significant strides in recent years. For those interested in fdm 3d printing made easy: a beginner's guide to getting started, understanding the essential components and their functions is crucial. This guide will provide you with a comprehensive overview of FDM 3D printing, ensuring you are well-equipped to embark on your printing journey.

What is FDM 3D Printing?

FDM 3D printing is a process that involves melting thermoplastic filament and extruding it layer by layer to create a three-dimensional object. This method is widely used due to its affordability and accessibility. But what makes FDM 3D printing so appealing to beginners? The answer lies in its simplicity and the availability of various materials.

Key Components of FDM 3D Printers

To fully grasp fdm 3d printing made easy: a beginner's guide to getting started, it is essential to understand the key components of an FDM printer:

- Extruder: This is the heart of the printer, responsible for feeding and melting the filament.

- Nozzle: The nozzle is where the melted filament is extruded onto the build plate.

- Build Plate: This is the surface on which the object is printed. It can be heated to improve adhesion.

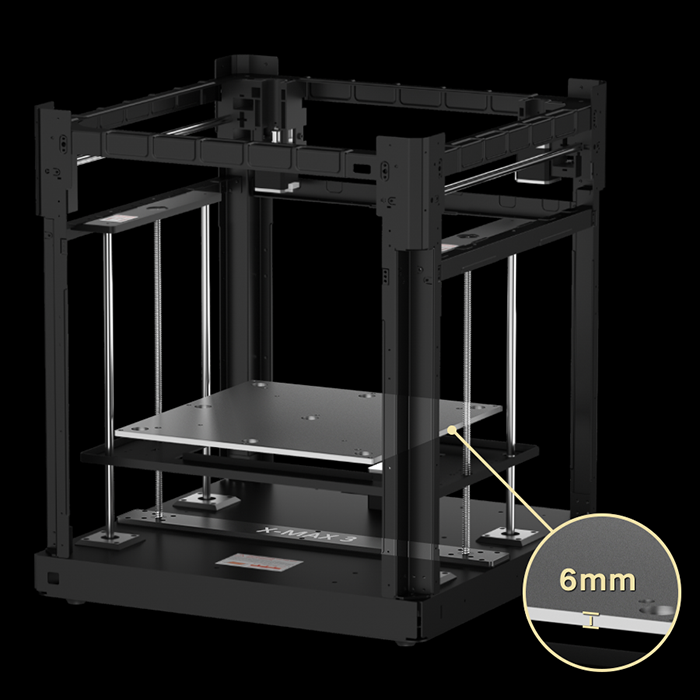

- Frame: The frame supports all components and maintains the printer's structure.

- Stepper Motors: These motors control the movement of the print head and build plate.

How FDM 3D Printing Works

Understanding how FDM 3D printing works is vital for beginners. The process begins with a 3D model, which is sliced into layers using slicing software. The printer then heats the filament and extrudes it through the nozzle, building the object layer by layer. If you are wondering how to achieve the best results, consider the following:

- Choose the right filament material for your project.

- Ensure your printer is calibrated correctly.

- Monitor the print process for any issues.

Getting Started with FDM 3D Printing

For those eager to dive into fdm 3d printing made easy: a beginner's guide to getting started, here are some steps to follow:

- Research and select an FDM printer that fits your needs.

- Familiarize yourself with the slicing software.

- Start with simple designs to build your confidence.

For a more in-depth exploration of FDM 3D printing, you can visit  . This resource provides valuable insights and tips for beginners. . This resource provides valuable insights and tips for beginners.

Conclusion

In summary, FDM 3D printing is an accessible and versatile technology that offers endless possibilities for creativity and innovation. By understanding the essential components and how they work, you can embark on your journey into the world of 3D printing with confidence. Remember, fdm 3d printing made easy: a beginner's guide to getting started is all about exploration and learning. Happy printing!

|