Guest

Guest

Dec 07, 2025

5:17 AM

|

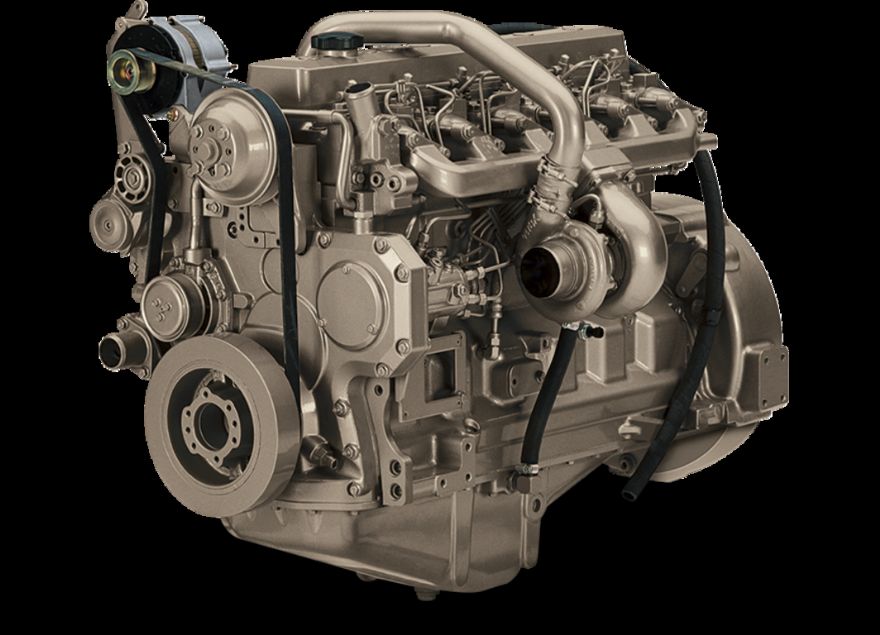

Heavy machinery is the backbone of construction, mining, and industrial operations. At the heart of every piece of equipment lies its engine—the component that powers productivity. Whether you are investing in a new or used engine, understanding the pros, cons, and key considerations is crucial for maximizing efficiency and minimizing costs.

New Heavy Machinery Engines: Reliability and Warranty

Opting for a brand-new engine ensures that your machinery operates at peak performance. New engines come with several advantages:

Reliability: A new engine is built to manufacturer specifications and is less likely to encounter unexpected failures.

Warranty Coverage: Most new engines include warranties, offering protection against defects and reducing potential repair costs.

Latest Technology: Modern engines often feature improved fuel efficiency, reduced emissions, and advanced performance capabilities.

The primary drawback of a new engine is its cost. For small businesses or projects with budget constraints, the initial investment may seem high, even though long-term reliability can offset the expense.

Used Heavy Machinery Engines: Cost-Effective Alternatives

Used engines are a popular option for businesses seeking to balance performance with budget. Benefits of purchasing a used engine include:

Lower Cost: Used engines typically cost significantly less than new ones, allowing companies to allocate funds to other areas of their operations.

Availability: Engines for older machinery models may no longer be in production, making used options the only viable choice.

Proven Performance: If sourced from reputable sellers, used engines often have a documented history of performance and maintenance.

However, used engines carry certain risks: potential hidden wear, reduced lifespan, and limited or no warranty. To mitigate these risks, thorough inspection and sourcing from trusted suppliers are essential.

Key Considerations When Choosing an Engine

When deciding between new and used heavy machinery engines, consider the following:

Budget: Assess your financial flexibility and long-term cost implications.

Machine Age and Condition: Older Brand new WP12.430E50 National V engine for Shaanxi Automobile 6x4 trucks machines may benefit from used engines, while newer machines perform best with new engines.

Maintenance History: Review records of previous maintenance and repairs if considering a used engine.

Availability of Parts: Ensure that replacement parts are readily accessible for the engine type you choose.

Operational Needs: High-demand projects may justify the reliability of a new engine, whereas short-term or low-intensity projects may be suitable for used engines.

Conclusion

Choosing between a new or used heavy machinery engine depends on a balance of cost, reliability, and operational requirements. While new engines provide peace of mind and advanced technology, used engines offer cost savings and accessibility for older equipment. Careful evaluation, thorough inspection, and sourcing from reputable suppliers can ensure that your investment supports productivity and longevity, regardless of whether the engine is new or used.

|